OnlyKem is a production and sales company focused on the refrigeration industry. In more than 15 years of cold storage export experience, we have formed relatively mature technical solutions in multiple vertical industries. For example, logistics-type cold storage, slaughtering plant, flower growing warehouse, etc., including special refrigeration equipment for fishing boats.

We first came across refrigeration equipment for fishing boats by chance. We replaced the refrigeration system of an old boat for a ship owner in Australia. This was a fresh and challenging job for us at the time. We have communicated and discussed the plan with the customer for several months. The customer gave us a lot of suggestions for the plan with his rich experience in use and maintenance. Our engineers also made a lot of feasible adjustments in the customer’s meeting. Customers expressed their appreciation and respect for our professionalism and research spirit, and finally we provided customers with a set of refrigeration equipment with good integration, easy maintenance and strong mechanical stability. The client was very satisfied with it and therefore introduced us to many of his friends. Thus we entered the Australian fishing vessel refrigeration industry.

At present, OnlyKem and Australia Raptis, Austop Fish, Fremantle Sardine, etc. have been maintaining this good partnership. Many lessons have been drawn from our many fishing vessel refrigeration retrofit projects. It also enables us to have quite mature fishing vessel refrigeration system solutions, and these solutions have also continuously proved their reliability and practicability in practice.

The environment on a fishing boat is very unstable compared to the land environment. Vibration, humidity, etc. are all severe tests for the stability of the refrigeration system. And there are very few engineers who are very proficient in refrigeration equipment among the general fishing boat personnel, so once there is a problem with the refrigeration system at sea, its rapid maintenance is also one of the essential qualities of professional refrigeration equipment for fishing boats.

When designing a refrigeration system on a fishing vessel, we usually need to consider the following aspects:

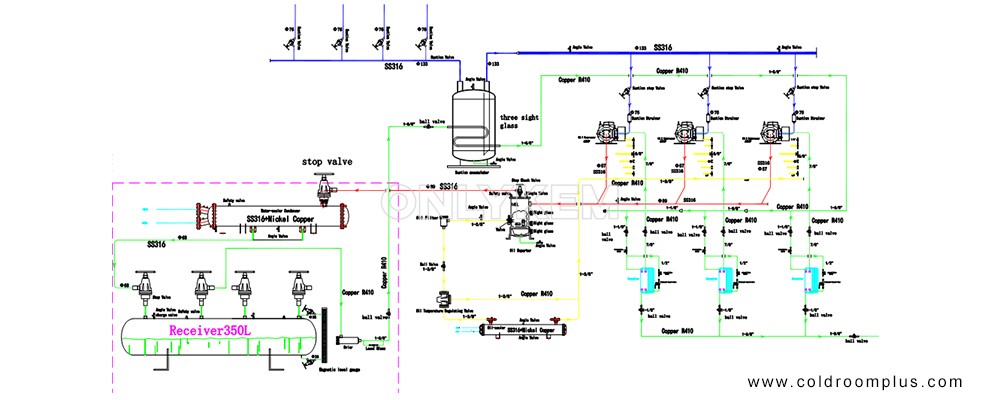

- Corrosion resistance. All of our units, evaporators and condensers have anti-corrosion treatment, so there is no fear of the erosion of equipment in humid environment.

- Enhance device stability. The shaking of the fishing boat is the most likely to cause the unstable oil level of the compressor and the insufficient oil supply. In response to this, we have made special improvements to the oil tank to ensure sufficient oil supply during shaking.

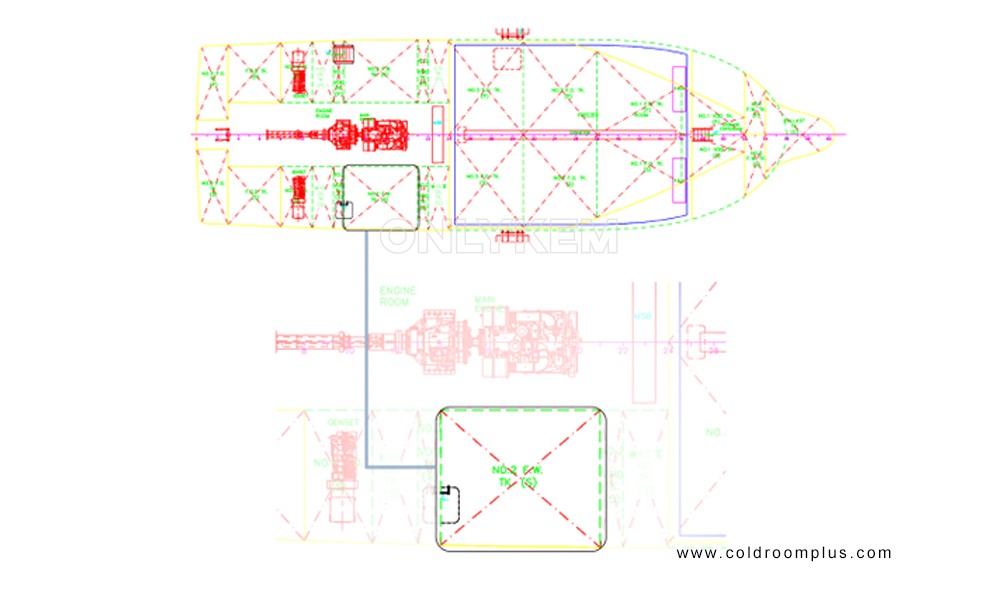

- Easy maintenance. Considering the small space inside the fishing boat, all the valves and other equipment will be designed to the same side, which is convenient for daily maintenance. In addition, mechanical control will be the preferred control method for the entire refrigeration system, and replacement of most vulnerable parts is very simple.

At present, OnlyKem is based on the Australian fishing boat refrigeration equipment market, and is also actively expanding into other markets, such as Vietnam, Suriname, etc. If you choose OnlyKem refrigeration equipment for your fishing boat. You will get:

- Ours special design with receivers, refrigerant stock standby.

- Only 4 valves, can switch to second system.

- Reliable safety valves for maintenance.

- Modular Refrigeration system design

- Convenient to load into your engine room.

- Easy to maintenance in your engine room.

- AS/NZS certificate quality

- Pressure vessel certificate.

- Electrical wire color regulation:

L1 Red, L2 White, L3 Blue, N Black.

Cable should be run in separate multi-cored cabling for different voltage.

- Mechanical material assure, CE certificate.

- All anto-corrosion assure, food safety, good for your food certificate application

- Stable mechanical control. Complete protection elements for all system,compressor, fan, pump, etc.

- Easy to control and maintenance., you can take some spare part.

- Not high request for your trawlers engineer, save your labor cost.

- All system can reduce cost.

- Service

- All engineers are 7×24 hours, 365 days service.

- Remote control for whole system, we can assist you to monitor the operation, can remind you when maintenance.