As the OnlyKem market continues to expand, display walk in cooler and freezer projects are no longer only used in the U.S. market. Recently we have once again received demand from Australian customers for display walk in cooler and freezer. Our technical team customized a display walk in cooler and freezer specifically for the customer based on the customer’s needs.

Our customer came to Australia. He owns two convenience stores and wants to buy two different types of coolers for his convenience stores.

The customer has been very interested in our products since 2021. Since the customer’s project has been waiting for approval, we patiently waited for the customer for three years. Our patience and professionalism have won the trust of our customers.

Inquiry for Australia’s Display Walk-in Cooler and Freezer combo

Customer info: Display walk in cooler and freezer combo.

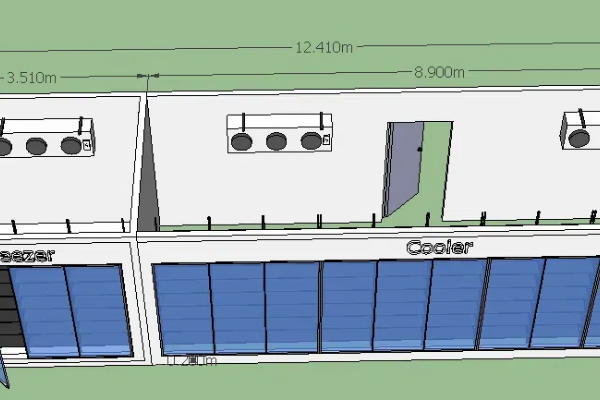

Project one info: 12.41*3.0*2.8m dimension.

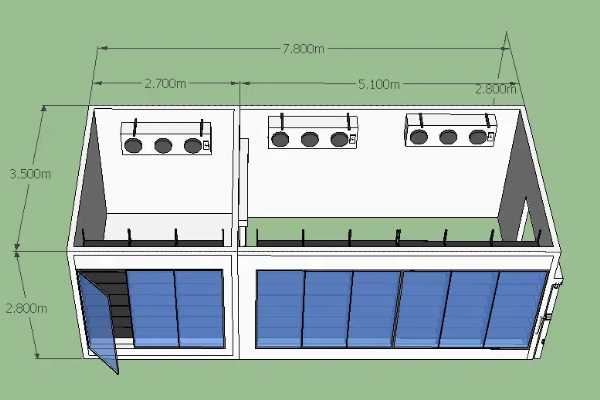

Project two info: 7.8*3.5*2.8m dimension

Features:

(1) Cooler:100mm PU panels with 0.426mm Galvanized steel without floor panel,and the U-shaped groove is fixed on the ground to fix the wall panel.

(2) Freezer:100mm PU panels with 0.426mm Galvanized steel with floor panel, with anti-slip aluminum plate to enhance the load-bearing capacity of the floor panel.

(3) The glass door frame reserves a 200mm threshold to avoid direct contact between the glass door and the ground, effectively preventing cold air leakage

(4) Wood blocks are embedded in the cooler panel opening, so that the glass door frame can be better fixed on it.

(5) The cooler access door is installed at the back and is specially designed according to the customer’s space.

(6) Project one: the cooler and freezer share a wall but don’t have a common entrance door.

(7) Project two: the cooler and freezer share a wall and the sliding door connects the cooler and freezer.

(8) Hinged door for project one: 100mm thick, double-sided 0.6mm galvanized steel plate

(9) Sliding door for project two: 100mm thick, double-sided 0.6mm galvanized steel plate

Condensing Unit for the Australia’s Walk in Coolers and Freezer Combo

Original Copeland Compressor, Gas R404A.

Condensing Unit Horsepower: 5HP for cooler and 3HP for freezer

No leakages, pressure test through out production, excellent workmanship.

Power saving design.

Intergrated modular assembly, factory pre-equipped refrigeration parts and electrical components, etc.

Standard Evaporator for the Australia’s Walk in Coolers and Freezer Combo

CE certificate;roof installation,Stainless steel bolts. Powder coating metal work.

(Including alunimun fins, copper pipe coil, fan etc)

IP 54 class protection, waterproof protection

Fin space: adopt 4.5mm, 6mm

Pipe diameter:15.88mm, high quality.

Glass Door for the Australia’s Walk in Cooler and Freezer Combo

- Glass door size: 30’’ by 79’’

- Glass frame color: Black, White and Silver

- Layers: 2 pane glass pack (cooler)/3 pane glass pack (freezer) with electric heater to avoid condensation (LOW-E Electric Heating Tempered Glass)

- 2/3 sets door per frame

- Door frame material: Aluminum alloy in black

- Self-closing function, Full length handle, Magnetic gasket, Power supply: 220v/50hz/1ph

- 90° Door stay open system

Shelf for the Australia’s Walk in Cooler and Freezer Combo

- Size: 30”*27″*83″

- 7 layers per set of shelves

- Aluminium alloy hook

- Stainless steel stanchion

- Post height 82″

- 30”*27”shelf tray

- Black price tag

- Default Loading capacity:100kg/layer

Protective Packaging of the Panel:

- Film packaging to prevent moisture, rust, and transportation scratches.

- Four-corner cardboard protection to prevent impact.

- Neatly placed, avoid shaking.

The Protective Packaging of the Refrigeration Unit:

- Wooden box: fix the compressor and fan to prevent shaking.

- Bottom support: easy to load and unload to prevent packaging damage.

The Protective Packaging of the Refrigeration Unit:

1.Wooden box: fix the compressor and fan to prevent shaking.

2.Bottom support: easy to load and unload to prevent packaging damage.

Protective Packaging of Glass Door:

1.Single glass door will be packaged with plastic film to prevent moisture, rust and transportation scratches.

2. Put the packed glass door in a wooden box for sorting and packaging to prevent the glass door from being damaged during transportation.

Protective Packaging of Glass Door Frame:

1.The glass door frame is wrapped with plastic film.

2. Put the wrapped glass door frame into a wooden box for repackaging to prevent damage caused by door frame shaking during transportation.

Protective Packaging of Shelf:

A shelf is packed together in a carton.