Food processing plants in the UK are used for processing and packaging of chicken, beef and mutton.

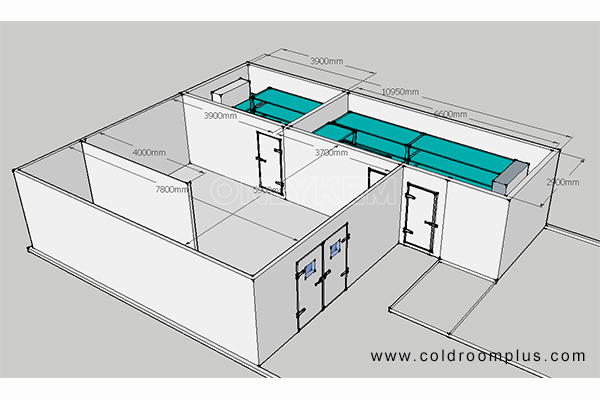

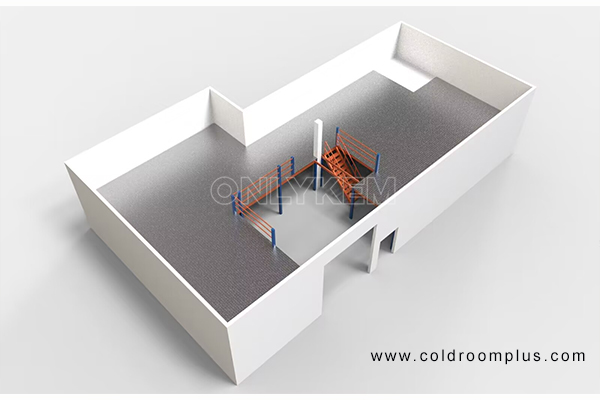

The background of the project is a processing room and cold storage built in the attic, the attic floor is made of industrial mezzanine floors.

The reason why the processing room is built in the attic is that there are many columns on the ground floor to support the mezzanine floor. The distribution of too many columns makes it inconvenient to work in the processing room, so it is built in the attic to avoid the impact of the columns.

Inquiry for UK Walk-In Coolers

Customer information: I need a processing room and a cooler and freezer room, can you provide a complete set.

Order information: The size of the processing room is 7.8×6.0x2.4m. Walk-in freezer size is 6.6x3x2.4m, walk-in cooler size is 4x3x2.4m. 100mm PU sheet and 150mm PU sheet with 0.6mm galvanized steel. Hinged door with aluminum plate

Condensing Units for Food Processing Room and Walk-in Cooler and Freezer

Original new Bitzer compressor and original new Copeland compressor, gas R404A, R507, etc.

World famous brand components: Schneider, Emerson, Castel, etc.

No leakage, full 2.8MPa pressure test, excellent workmanship

power saving design

Air Cooled Condenser for UK Walk-In Freezer and Processing Room.

The cabinet body is steel plate sprayed with plastic, anti-corrosion

Mechanical expansion tube, aluminum fins, external fan, better heat transfer effect, durable

Tested under 2.8MPa air pressure, without any potential leakage

Nitrogen blows away all contamination in the piping system, ensuring a longer service life

Double-side air-cooling fan, the wind is soft, suitable for workers to process.

FAQ

- How to solve the drainage system of the processing room located in the attic?

A custom-made PU panel with drainage grooves is adopted, and the surface material of the PU panel is 3mm thick stainless steel.

- Has the processing room been built in the attic considering the load-bearing capacity?

The processing room is built in the attic, which is a solution that we have chosen to meet the load-bearing standards after accurate calculation and communication with the plywood floor supplier.