Cold Room Panel is made of PU foam, also called PU sandwich panel, PUR Panel in which polyurethane foam is been sandwiched between the two outer galvanized steel covers. CFC-free insulated PU panel is commonly specification we supplied. B2 level fireproof can make sure the project during building and operation far away from fire accident.

Our cold room panel project in USA, it is for a vegetable process factory, there is process workshop, preparation area and cold room.

OnlyKem cold room in USA.

- Cold Room Dimension: 12m*8m*4muse for vegetable after processing.

- Process workshop Dimension: 8mx5mx3m. for vegetable processing.

- Precool area, dimension 8mx3mx3m. for vegetable preparation before loading in Processing workshop.

- Cold Room Inside Temperature: 0℃.

- Precool area temperature: +15℃.

- Process workshop temperature: +12℃.

The vegetable Our customer collect from farm, +35 ℃, Same temperature with ambient temperature.

Need to put them into precool area to cool to +15℃ first, and then do necessary process and packed, transfer to cold room for long time store.

Cold room panel in USA specifications

| NO | Item | Specifications |

|---|---|---|

| 1 | Core | Polyurethane (P.U.) Foam |

| 2 | Density | 40+-2kg/m3 |

| 3 | Blowing Agent | Cyclo-Pentane |

| 4 | Skin: Plain or Corrugated type | Polyester Resin Coated G.L. (Galvalume) and G.I. (Galvanized Iron) |

| 5 | Thermal Conductivity | 0.018k Cal/mh℃ |

| 6 | Effective Width | Standard: 960mm |

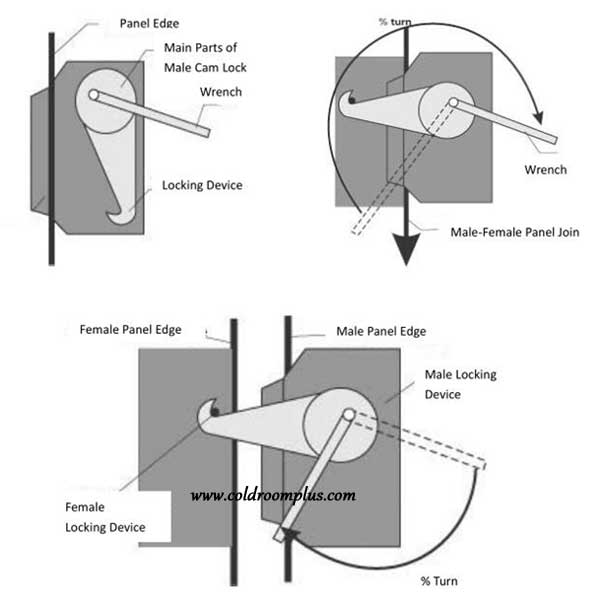

| 7 | Edd Connection | Tongue and groove / plain |

Cold room Panel Features

OnlyKem PU panels are:

- Suitable for low and high temperature controlled application.

- Offer high thermal performance, maintaining the temperature of the internal environment.

- Provide low air leakage performance

- Significantly reduce energy usage and running costs

- Provide a panel system which effectively controls temperature flows, Vapour and humidity levels.