Suppliers, manufacturers, and sales of OnlyKem cool room panels

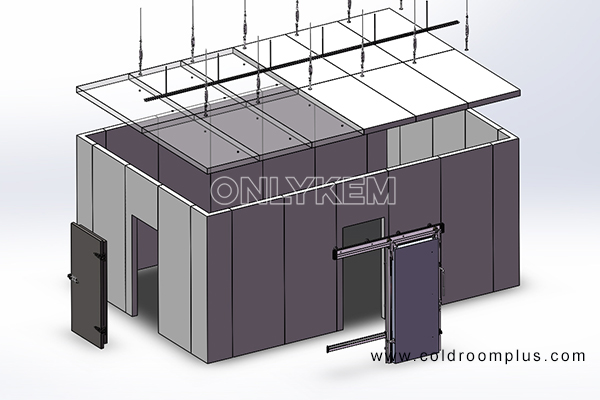

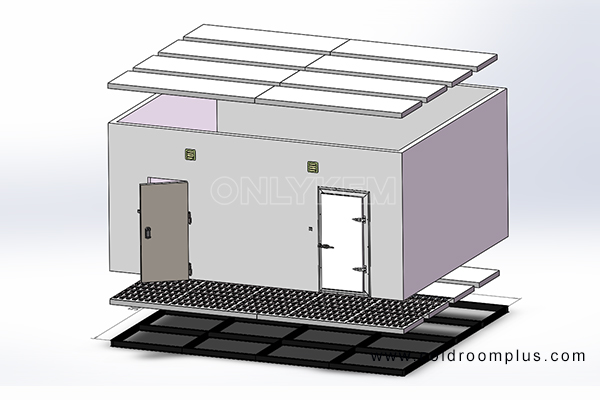

We provide insulated cold room panels in any desired insulations, sizes, and thicknesses, tailored specifically to your requirements. The insulated cold room panels are available to our customers as ceiling, wall, and floor panels. OnlyKem panels are designed to assist in stabilizing the temperature and extending the shelf life of your products.

Cold Room Panels

At OnlyKem, our goal is to offer a complete solution for all your insulated panelling needs. We are able to provide a one-stop shop for all of your needs for an insulated cold room thanks to our extensive selection of panels and flashings.

Core Thickness

Outer Sheet

Insulation Type

Length Options

Insulated Panels

Suppliers, manufacturers, and sales of OnlyKem cool room panels

Cold Room panels are utilized in climate-controlled environments where maintaining the right temperature is crucial and must adhere to very strict specifications. From -36°C to 20°C., our insulated cold room panels can withstand both positive and negative temperatures.

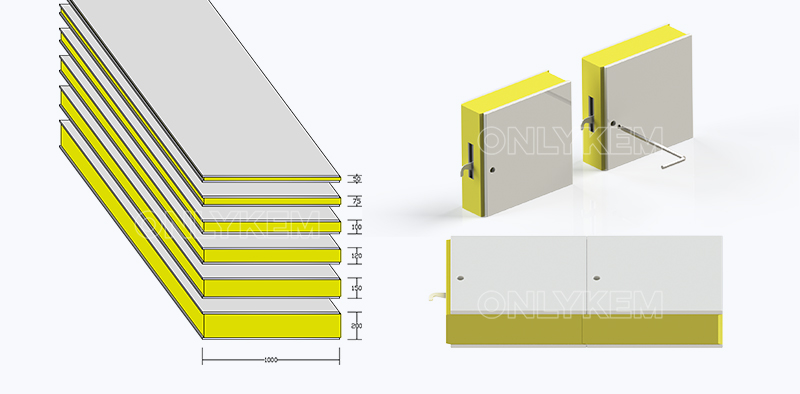

Our panels are energy-efficient and energy-saving due to their great insulating lightweight with low thermal conductivity qualities that reduce the amount of energy needed for cooling. During the manufacturing process, closed-cell insulation is injected between sealed metal plates, resulting in an insulated cold room sandwich panel. The usage requirements are in compliance with current regulations.

PIR Panels

PIR is hard to beat in terms of overall panel performance. Insurer-approved levels of fire resistance, a remarkable strength-to-weight ratio, hygienic and temperature management, and quick build times are all provided by PIR core panels. All sanitary cold, chill, and ambient environments can use fire-rated PIR wall and ceiling panels.

Up to one hour of fire resistance is offered by PIR cores. When PIR is in contact with flame, it develops a robust carbonaceous char that prevents the core foam from igniting. Industry-wide, PIR is acknowledged as the fire-safe substitute for other foam cores including polyurethane and polystyrene.

- Core Material – PIR

- Fire Performance – B1

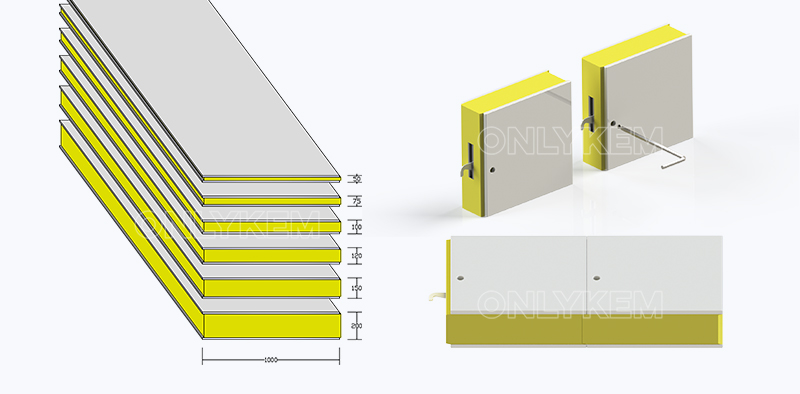

- Core Thickness = d (mm) – 50 | 75 | 100 | 120 | 150 | 200

- Outer Sheet Thickness (mm) – 0,45 – 0,50 – 0,60 – 0,70 – 0,80

- Inner Sheet Thickness (mm) – 0,35 – 0,40 – 0,45 – 0,50 – 0,60 – 0,70 – 0,80

PUR Panels

The closed-cell rigid polyurethane foam used in the polyurethane insulation is made of two completely CFC-free blowing agents. The foam has been tested in conjunction with steel, aluminium, and GRP panel facings and has demonstrated excellent adherence and density distribution.

The closed cell structure of PU insulation ensures a high level of vapour and air resistance for the duration of the product life. This makes it possible to find effective and resource-saving ways to accomplish the airtightness of the building envelope, which is one requirement for structures that use almost no energy.

- Core Material – PUR

- Fire Performance – B2

- Core Thickness = d (mm) – 50 | 75 | 100 | 120 | 150 | 200

- Outer Sheet Thickness (mm) – 0,45 – 0,50 – 0,60 – 0,70 – 0,80

- Inner Sheet Thickness (mm) – 0,35 – 0,40 – 0,45 – 0,50 – 0,60 – 0,70 – 0,80