Industrial Freezer Rooms are the facilities that use a variety of refrigeration equipment to maintain a stable low temperature for cold storage. The storage temperature of the industrial freezer room is generally from -20°C to -25°C.

Many products food such as ice cream and seafood need to be stored at a frozen temperature of -25°C without deterioration, for example, if the ice cream does not reach -25°C during storage, its aroma will be gone, the taste will be deteriorate.

Industrial Freezer Rooms Features

When food is put into the cold storage room, the storage temperature will gradually reach -25°C after a period of time. There is no special cold storage design process and technical requirements during this period. The storage temperature of this cold storage is between -22 °C ~ -25 °C, this is the typical cold storage temperature of the walk in industrial freezer room.

Compared with cooler room, the mechanism of action is in large difference. If temperature is too low, it will cause the death of foods such as meat and seafood cells, and the degree of freshness will be greatly affected. Therefore, for the storage of fruits and vegetables, it doesn’t mean the lower the temperature, the better.

The Applications of Industrial Freezer Rooms

Industrial Freezer Rooms are useful for store raw materials and food, frozen storage of industrial/commercial products; foods, dairy products, meat, aquatic products, poultry, pharmaceuticals, chemical raw material or performance tests for certain products used in industrial manufacturing processes.

Freezer cold room insulation system and refrigeration system

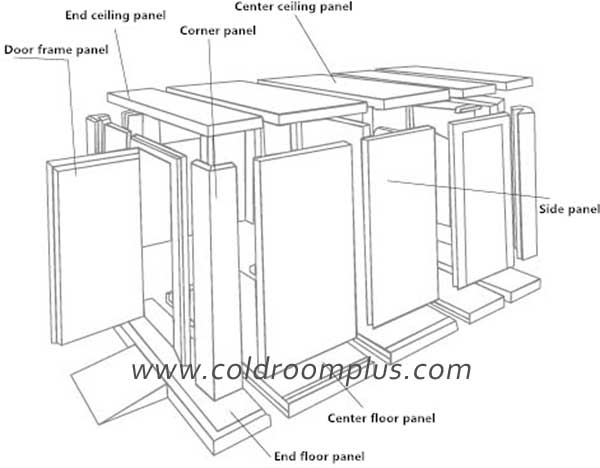

Panel system:

Our mould can produce 50mm , 75mm , 100mm , 120mm, 150mm , 200mm thickness panel. For industrial freezer rooms , we suggest to use 120mm or 150mm thickness .

Cold storage panel sandwich use PU high pressure foaming. Taking metal materials like color steel sheet, stainless steel plate or some other materials as surface .

Generally polyurethane refrigeratory are combined refrigeratory , assembled by polyurethane panels , it can be assembled in different width and height . We have panels width take 960mm or 1000mm as module , nonstandard size can be customzed separareky. Internal pre-embedded cam-lock , scientific design, compact installation, strong sealing, easy construction.

Cam-lock connection cold room pu panel :

Small Tips:

Different with cooler room, the foundation of the freezer room is affected by the low temperature and the moisture in the soil is easily frozen. Due to the volume expansion after the soil freezes, it will cause ground cracking and deformation of the entire building structure.

For this reason, in addition to having an effective thermal insulation layer, the floor of the low-temperature freezer room must be treated under the thermal insulation layer in order to prevent the freezing of the soil.

At present, the domestic and foreign cold storage floor heat treatment methods mainly include the following types:

First, the overhead floor. It can be divided into two kinds of high overhead floor and low overhead floor. The elevated platform is a basement below the first floor of the cold storage. The basement can be used for air temperature or other purposes. In the low-rise, the first floor is lifted by a beam-slab system or a ridge wall. No matter whether it is an overhead or low-elevation floor, the cold storage base soil is separated from the floor by an air space to cool the interior of the building. The amount will not be directly transmitted to the subsoil, but the temperature of the inter-air layer can still cause freezing damage to the subsoil.

Second, ventilated floor. In the cold storage floor below the insulation layer buried ventilation ducts. Ventilation pipes are generally laid with cement pipes or cylinder tiles. Ventilation floor can be divided into natural ventilation and mechanical ventilation. The natural ventilation floor is based on outdoor air as the heat source. When the outdoor air passes through the ventilation pipe under the effect of hot pressure and wind pressure, it will continuously replenish the heat, so that the lower part of the insulation layer of the cold store is always maintained above 0°C.

The ventilated floor uses a method of sending steam into the ventilation ducts to increase the temperature in the lower part of the insulation layer of the cold storage.

This method is generally used during the heating season. Usually fans are used to send outdoor air into the ventilation ducts. Natural ventilation floors are generally used for cold storage in areas with short depths and high outdoor temperatures in winter. Mechanical ventilation floors are generally used for large-scale cold storage, but ventilation ducts must be organized through ventilation ducts for planned heat transfer.

Refrigeration System for industrial freezer rooms

Compressor is the most important equipment in refrigeration equipment (It often referred to as the host refrigeration equipment) . We mainly offer original new Bitzer and copeland brand compressor.

Compressor compresses the lower pressure steam into higher pressure steam, which reduces the volume of steam and raises the pressure. The compressor sucks in the lower-pressure working fluid vapor from the evaporator to increase the pressure and send it to the condenser. The condenser condenses into a liquid with higher pressure. After the throttle is throttled, it becomes a liquid with a lower pressure. Low liquid is sent to the evaporator, absorbs heat in the evaporator and evaporates into low-pressure steam, and is sent to the inlet of the compressor, thereby completing the refrigeration cycle.

We provide specially temperature refrigeration equipment for industrial freezer rooms. Our engineer use professional software to calculate the design proposal then choose the most suitable condensing unit and evaporator according to customer’s requirements. So it can save customers’ using costs while meeting customers’ refrigeration demand.

Maintenance of the industrial freezer rooms

- After the installing of cold storage room or reusing after long-term decommissioning, the cooling rate should be reasonable, it is advisable to control it at 8-10°C per day, and maintain it at 0°C for a certain period of time.

- cold storage pu panel maintenance. Please pay attention to the use of hard objects on the panels collision and scratching. Because it can cause dishing and rusting of the panels, it will seriously reduce the local insulation performance .

- Set with regular defrosting , change filters regularly, etc.

- cold storage ground maintenance, general small assembly-type cold storage floor using insulation panel, use the cold storage should prevent the floor panel from a lot of ice and water, if has ice there, cleaning must not use hard objects beat, damage the floor panel.

OnlyKem is professional cold room manufacturers , committed to design, manufacturer , and export our walk in freezer room, chiller room , blast freezer room etc.

If you have any questions or inquiries, please contact us at sale@coldroomplus.com, we will reply as soon as possible. Choose OnlyKem , fresh life with you always!